| Composition | Nano - GaInSnZn |

| Thermal Conductivity | >15W/m·K |

| Specification | 5g, 10g, 100g |

| Conductivity | 3 X 10^6 S/m |

| Viscosity | 8200 mPa·s |

| Operating temperature | -50℃~600℃ |

| Volatilization rate | <0.001% |

| Corrosive | Aluminum corrosion |

| Composition | Nano Technology - GaInSnZn |

| Thermal Conductivity | >20W/m·K |

| Specification | 5g, 10g, 100g |

| Conductivity | 3 X 10^6 S/m |

| Viscosity | 6000 mPa·s |

| Operating temperature | -50℃~600℃ |

| Volatilization rate | <0.001% |

| Corrosive | Aluminum corrosion |

| Composition | Nano Technology - GaInSnAg |

| Thermal Conductivity | >25W/m·K |

| Specification | 5g, 10g, 100g |

| Conductivity | 3 X 10^6 S/m |

| Viscosity | 4000 mPa·s |

| Operating temperature | -50℃~600℃ |

| Volatilization rate | <0.001% |

| Corrosive | Aluminum corrosion |

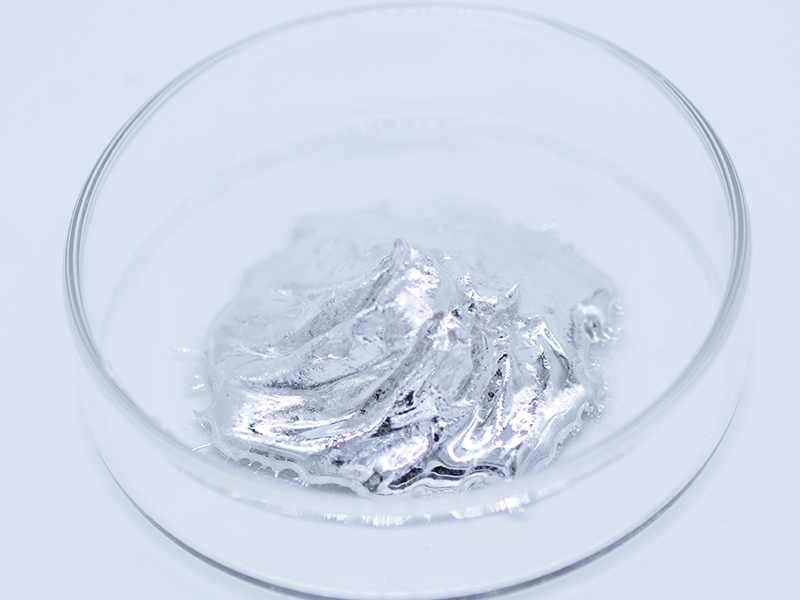

This Liquid Metal Thermal Paste is made of 100% metal material by using our newest nano technology and adding nano metal powder into liquid metal, its thermal conductivity reaches 20W/m·K minimum. It has great adhesivity and high temperature resistance, and is non-flowing, non-volatile, non-oxidative at high temperature environment. It has wide range of working temperature and good thermal shock resistance, and great ageing resistance. It is a great substitute of Silicone Grease and can be applied to IGBT cooling and LED cooling, power battery and CPU/GPU cooling. This thermal paste also has good electric conductivity and has good potential application in Printed Circuit Board, solar energy conductive paste, etc. It can ensure long-term operational safety of heat dissipation systems for its strong stability and reliability. Also, its viscosity and fluidity are controllable and adjustable according to customer’s requirement.

Liquid Metal Thermal Paste is certainly RoHS conformable and absolute nontoxic, and can be directly coated on the surface between heat source and heat radiator in thickness of 0.05mm to 0.2mm for fast cooling. It is compatible with copper and stainless steel without emitting organic substance.